P.EDLC is a supercapacitor tailor-made for mid-frequency applications at 100Hz, while bringing key performance parameters to power electronics: high-power, fast charging, extended life cycle and tolerance to high temperature.

Planar supercapacitors: breaking the status quo

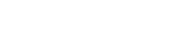

The P.CAP project develops energy storage devices aimed at modern electronic devices that require reliability, miniaturization, and tolerance to high temperatures. These devices serve as an alternative to traditional capacitors since they are novel SMDs (Surface-Mounted Device) that are compatible with reflow, have higher reliability, and are high temperature-resistant. We have also eliminated tantalum, making these devices more sustainable and less prone to supply chain disruptions.

P.CAP currently has 2 product lines: P.EDLC and DC.CAP. Both provide SMD and reflow-compatible devices operating at high temperatures.

DC.CAP

DC.CAP is a supercapacitor for backup and peak power applications. With its compact design and reliable operation up to 105ºC for 2000h, DC.CAP surpasses the limits of commercially available supercapacitors.

The impact

Increased reliability

Increased reliability

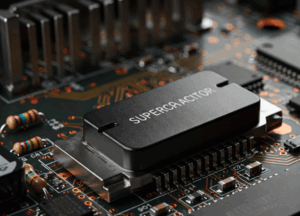

Product failure is an expensive burden. Capacitor failure is more likely to happen in high working temperature or under intense vibration.

P.CAP is currently designed to operate for over 1000 hours at temperatures of at least 105 °C, with potential for further enhancement as development progresses.

Better product integration

Better product integration

P.CAP can solve your problems of vibration and size during product assembly.

The combination of its planar shape, SMD connection and high capacitance translates to a low-profile device that can be assembled with a high mechanical integrity using an automated line.

Sustainable Design

Enabling new technologies

and applications

P.CAP does not contain any critical raw material nor conflict mineral such as tantalum, ensuring a more sustainable supply chain.

Tantalum is a conflict mineral widely used in electrolytic capacitors, which are adopted in applications working at low voltage and with mid to high frequency.

P.CAP is tantalum-free and has an extended product lifetime. In that way, we not only generate less electronic waste but also ensures a more sustainable supply chain.

Check out our white papers

Capacitors and Supercapacitors: Technology Overview and Future Trends

Energy storage plays a crucial role in modern electronics, enabling devices to function efficiently and reliably. Capacitors and supercapacitors stand out due to their versatility and use in a wide range of products, from consumer electronics and industrial systems to renewable energy solutions and electric vehicles.

High-Temperature Effects on Capacitor Performance: A Focus on Component Stability

Recently there has been an increasing need for electronic components, such as capacitors and supercapacitors, to work in harsh environments. From industrial machinery to aerospace and renewable energy systems, electronic systems are now deployed in applications where they must endure extreme conditions, such as high temperatures, elevated pressures, and severe mechanical stresses. This presents significant technical challenges, requiring advanced designs and materials to ensure that components can maintain performance and reliability under such conditions.